Pioneering safer, lighter, and more sustainable vehicles in Europe

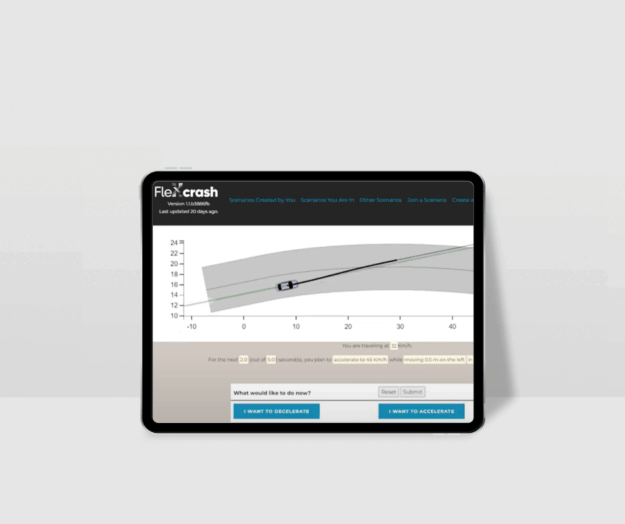

As the shift toward sustainable mobility accelerates, the automotive industry faces the challenge of creating vehicles that are lighter, safer, and more environmentally friendly. The FlexCrash, Sup3rForm, and Safe&Clean projects, funded by the EU Research Fund for Coal and Steel (RFCS), are driving this transformation through innovative solutions that merge lightweight design, crash performance, and sustainability — shaping the future of mobility in Europe.